Shengfan Alumina Ceramic:

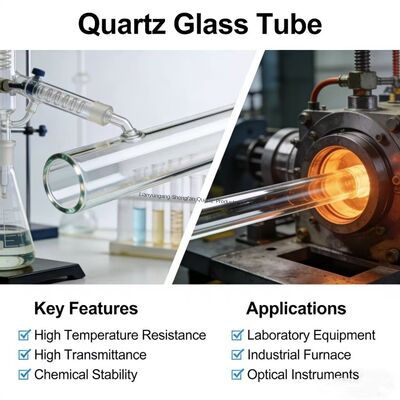

Siamo un produttore di forno a tubi di quarzo trasparente.

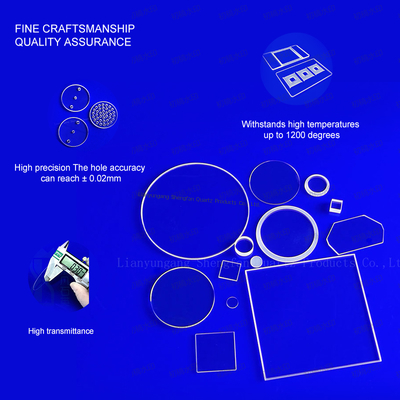

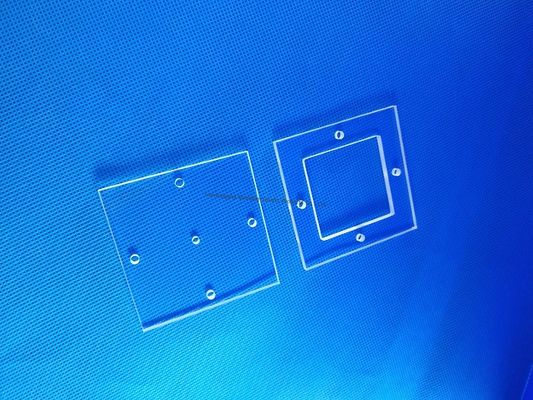

Dimensioni e design: accetta la personalizzazione in base a diversi diametri, spessori, lunghezze o invia il tuo disegno.

Descrizione del prodotto:

Alumina Parti ceramiche sono utilizzati per parti rotanti in e inmacchine per la fotolitografiaQuesto richiede una precisione di lavorazione estremamente elevata, e la portata del cerchio interno deve essere entro 2 micron.

Le ceramiche fini sono diventate componenti chiave delle apparecchiature semiconduttrici.è necessario utilizzare ampiamente componenti in ceramica con composito funzionale, stabilità strutturale, stabilità termica e alta precisione dimensionale.

Altre parti ceramiche ad alta precisione utilizzate nell'industria dei semiconduttori Le ceramiche di precisione sono diventate componenti chiave delle apparecchiature per semiconduttori, compresi i forni a singolo cristallo,attrezzature per l'impianto ionico, macchine per la fotolitografia, apparecchiature CVD/PVD e apparecchiature di imballaggio e di collaudo.

Innovacera è in grado di fornire i materiali richiesti, tra cui ceramiche di allumina, ceramiche di nitruro di alluminio, ceramiche di nitruro di silicio, ceramiche di nitruro di boro//ceramiche di nitruro di boro pirolitiche,Carburo di silicio e ceramiche microporose.

Equipaggiamento di produzione:

Profilo aziendale:

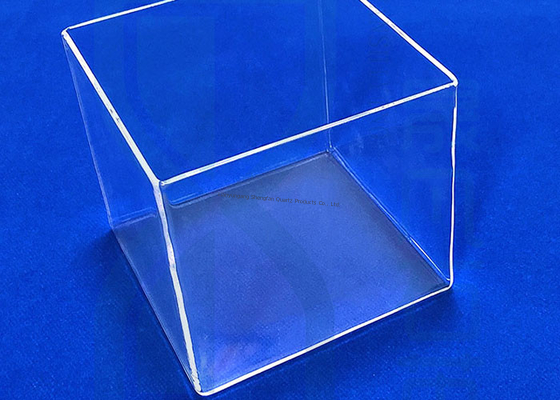

Lianyungang Shengfan Quartz and Ceramic Product Factory è una fabbrica professionale specializzata nella ricerca e sviluppo di piastre di quarzo, tubi di quarzo, flange di quarzo, anelli di quarzo,strumento a cuvette e quarzo.

L'azienda si trova nella città di Donghai, provincia del Jiangsu, in Cina, a 70 km dal porto di Lianyungang.Ora abbiamo più di 30 dipendenti.,con un fatturato annuale superiore a 5,2 milioni di dollari.Con la filosofia di orientamento tecnologico, qualità prima,integrità e responsabilità,operazione sostenibile,la società si impegna a costituire un'impresa internazionale con capacità operativa standard e sostenibile.

Imballaggio:

FAQ:

Posso avere un ordine di campione? A: Sì, accogliamo l'ordine di campione per testare e controllare la qualità.

Q2. Che ne dici del tempo di consegna?

Q3. Hai un limite di MOQ? A: MOQ basso, 1pc per il controllo dei campioni è disponibile

Q4. Come procedere con un ordine nella vostra fabbrica?A: Innanzitutto, fateci conoscere le vostre esigenze o applicazione. In secondo luogo, citiamo secondo le vostre esigenze o i nostri suggerimenti. In terzo luogo, il cliente conferma i campioni e deposita per l'ordine formale..In quarto luogo organizziamo la produzione.

Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!  Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!